People have a lot of questions not only about my kinetic sculptures, but also regarding our history in the craft world. Over many years, Marji and I built a business that has defied the odds and became a career. Recently discovered photos brought down from a dusty attic shelf have inspired this series of blog posts chronicling the evolution of Wood That Works.

Amazingly, it started pretty much on a whim. I had been designing small, wooden children's toys and "executive playthings" as a way to fill the empty time at a boring programming job. Not only did the doodling fill time but it also provided a way to work with my hands on nights and weekends. Building things had always been a favorite pastime. Location wasn't in my favor and my workshop was the second bedroom of our small second floor apartment. I can't imagine what the downstairs neighbor thought!

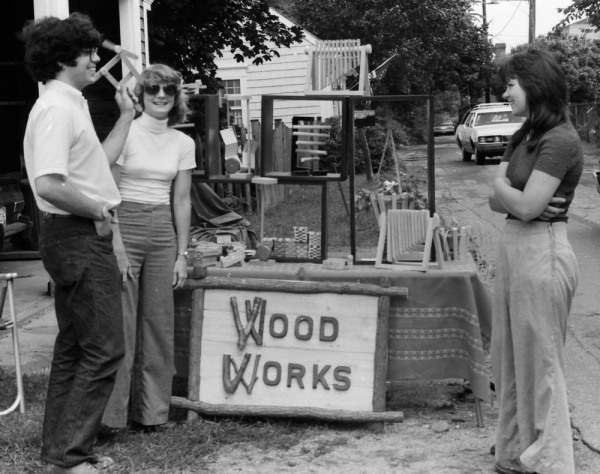

When I discovered that I enjoyed the "toy" work more than the "real" job, I quit the practical job (during a recession no less -– ah, the confidence of youth!) and started showing my work at small craft fairs under the name Wood Works. (The "that" was added with the wall pieces). There wasn't a business plan guiding WTW with goals and a mission statement as many entrepreneurial pursuits require today. I assumed I'd have to go back to a paying job at some point. It was the 70's, Marji had a teaching job she loved and it didn't cost us much to live. The lack of a traditional business structure allowed WTW to change with the evolving craft market that was still in its infancy in the mid to late 1970s.

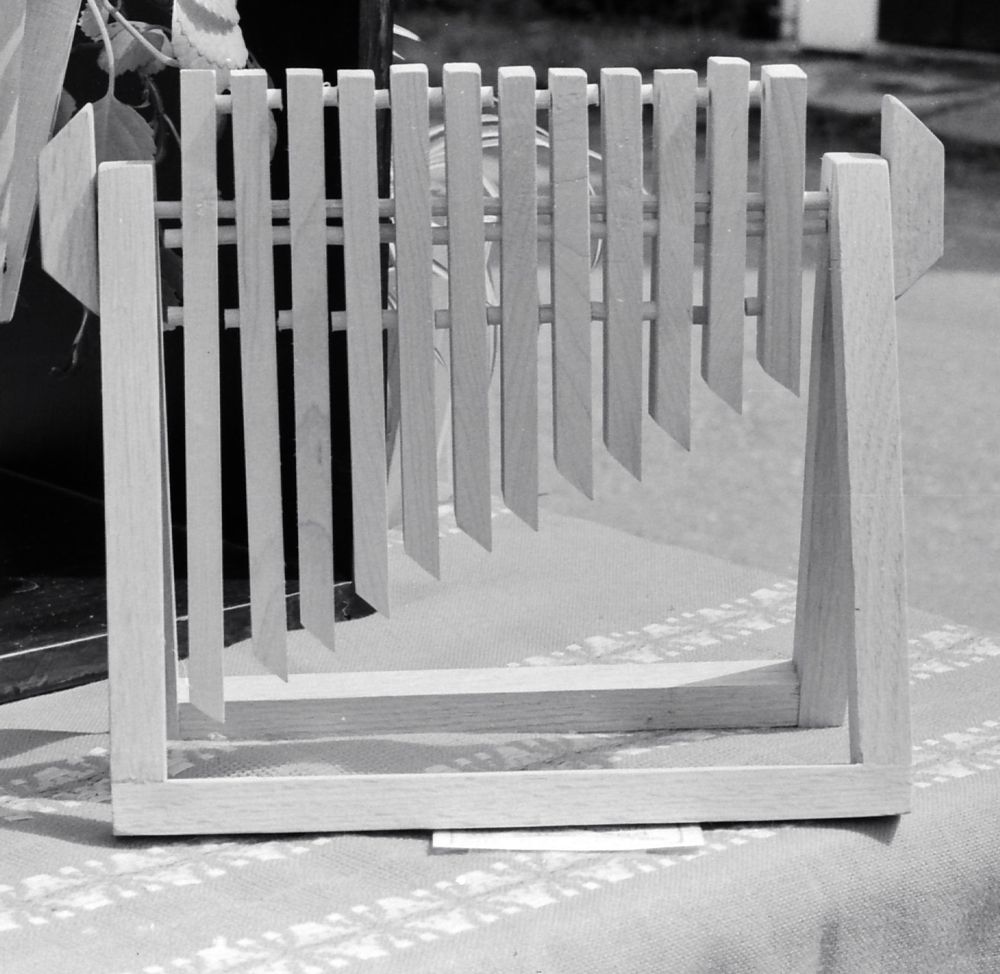

In the beginning, the craft shows where I displayed were small gatherings, located in varied venues including grassy fields, church basements, and high school gyms. I showed my work, talked to people, and made a little money. Our big sellers were classic toys like the Do-Nothing Machine and Jacob's Ladder. They sold for about $5 each. We learned that people liked the toys that moved and I designed a line of motion toys – Zylo, Spinner and Gizmo with Zylo as the king of our "high end" market.

We had to sell an over-whelming number of pieces to make a profit never mind a living. I was doing the assembly work myself with family help and had no intention of scaling up to include employees. I never saw myself as a boss! Something had to change if this was to have any future. I realized that in order to make this endeavor more profitable I would have to design something unique that would appeal to buyers in this fledgling market.

It was during this time that, through a strange and serendipitous route, we learned of a rental in rural Woodstock, CT. It was part of an old farm and not only did it have charm, it also had shop potential! The old barn was long gone but a cinder block milk shed was still standing and, if we cleaned it out, I could use the space. Marji and I moved from the inappropriate apartment workshop and setup my first real (although cold) workshop. It was time to broaden my product line.

One of the comments often shared with us, especially with regards to Zylo, was that it didn't run long enough. That started me thinking about ways to make things move for longer periods. I knew how clock escapements worked and they ran for long periods but didn't find the motion of a pendulum very interesting. I decided to try making a weight-driven escapement that would move something other than a pendulum. I did lots of experiments and built several pieces that moved including a large freestanding clunker of a piece we called Albert that was powered by a 20 pound weight, hardly moved, and ran for 20 minutes. I gradually refined the ideas, moving the concept to the wall. I came up with three designs that used five pound weights and ran reliably for about a half hour, B.W Cornwallis, Inventor Released and Wandering Asterisk.

I first presented the wall-mounted pieces to the public at a weekend "tent" show in Farmington CT. We mounted the pieces on my utilitarian but decidedly ugly shop test stands and put them behind our table display of toys. We hoped they would attract people to our display and inspire them to buy toys. After a lot of discussion between Marji and I, we put the insanely high price of $95 on each of them. At that point our high priced Zylo was $15! I didn't think they would sell but I knew I couldn't make them for less.

To my amazement and joy we immediately attracted a mesmerized crowd and in about 20 minutes sold the original working models of all three. I remember walking around the outside of the tent that weekend finally seeing a future that might actually work. I had lots of ideas for new mechanisms and designs churning in my head. It's one of those highlight moments that has stayed with me. I also realized that I had found that elusive niche that would be seen as unique in the growing craft market.

We did have a lot to learn however. I had sold my only prototypes. I had to go back to the drawing board (literally) and remake the sculptures from memory!

To continue to part 2: Click Here